by Don Clow

INTRODUCTION

The streets of the City of London may not have been paved with gold but in the nineteenth century they were certainly much better paved than most of London or other urban areas of the United Kingdom. Although a good visual impression of Victorian London can be gleaned from many available contemporary photographs, it is very difficult to recapture the forceful impact on the senses of noise, smell, dust and mud, attributable to the state of the road surfaces. This article is in two parts, the first describes the development of pavings from unbound Macadam roads, through the early use of tar to the introduction of stone setts. The second part (forthcoming) will concentrate on wood block paving, asphalt and less-frequently encountered types. The period covered was one of rapid change in the Metropolis consequent on the growth of commerce and industry, and the expanding population. At the beginning of the Victorian era, London was by far the largest manufacturing centre and the major port of the country; large railway goods depots were established in the central area as the century progressed and this added greatly to the cartage traffic. Industry, especially in the eastern part of the Metropolis, made onerous demands on the physical structure of principal roads.

Paving was not only for the benefit of horse-drawn traffic and pedestrians but also regarded as an important factor in public health. At mid-century, many of the poorest districts were unpaved, unsewered and only fitfully served by cleansing contractors. Refuse, including excrement and household rubbish, would be dumped in the street fouling the surface, allowing obnoxious fluids to saturate the structure, providing a breeding ground for disease-carrying flies as well as air- and water-borne germs. An impervious paved surface at least gave scope for effective cleansing.

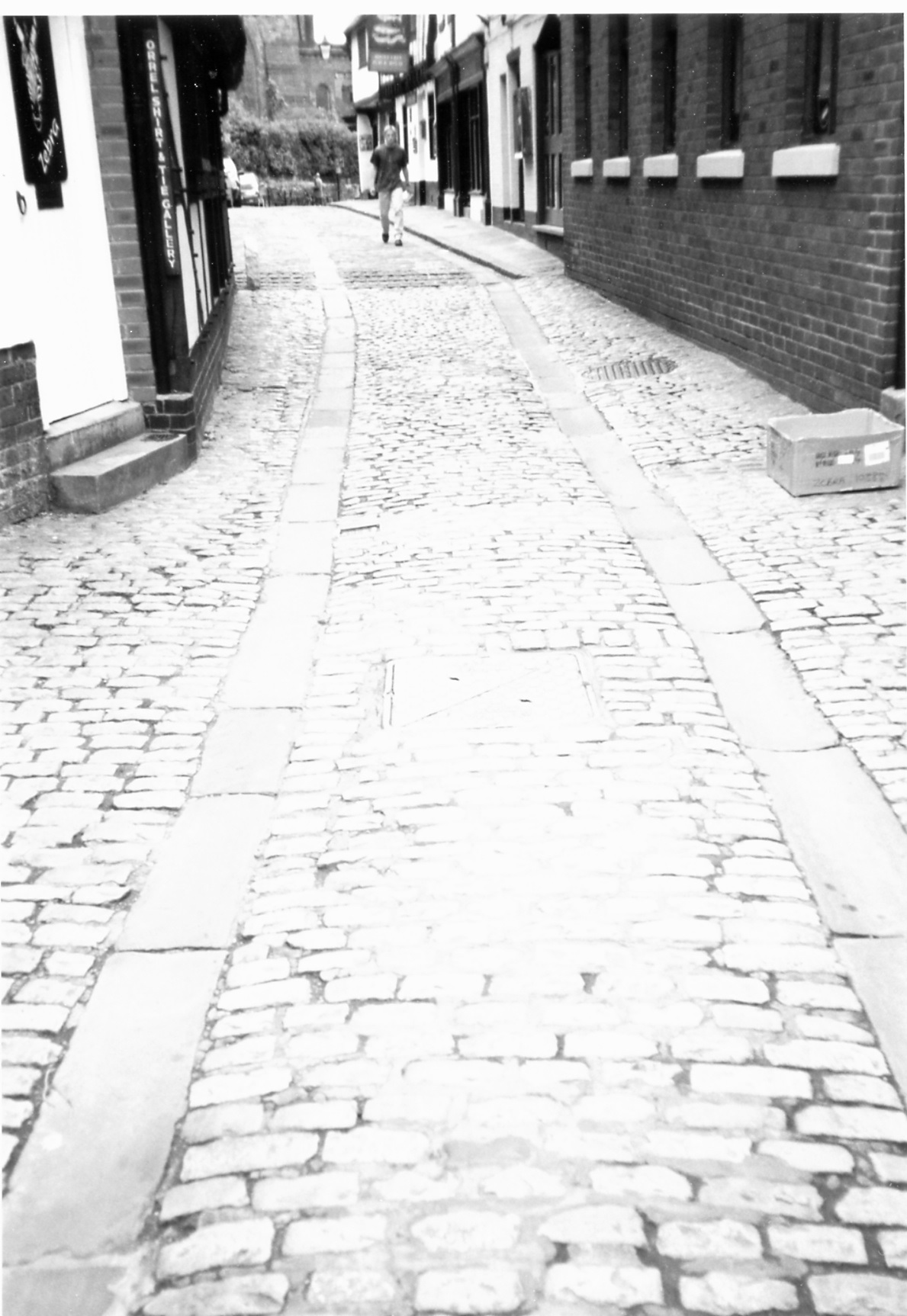

At the beginning of Victoria's reign some streets were still surfaced with either 'cobbles' (large water-rounded stones collected from beaches), irregular shaped flat stones 6 to 8 in. across, or else they were roughly-gravelled tracks (Photo 1). The main varieties of carriageway paving considered are water-bound Macadam, tarred Macadam, tar-macadam, stone sett, (Photo 2) wood block and asphalt. Of the documentation available on the paving of roads in London in the nineteenth century, four sources are especially useful. One 1 records developments in the most prestigious authority, the City of London during the time of William Haywood, the others 2-4 summarise the practices of a number of metropolitan authorities. Haywood was the Engineer and Surveyor to the Commissioners of Sewers in the City of London from 1846 to 1894. The Commissioners' responsibilities included the maintenance of the highway. Haywood was an outstanding engineer, regarded by Sir Joseph Bazalgette as 'foremost in Britain in matters of street alignment and paving'. Haywood took considerable interest in the nature of the road surface for economy in construction and maintenance, safety in view of the high accident rate to horses, dust generation, ease of cleansing, and the noise generated by the iron-shod wheels of vehicles. The heavily-trafficked streets of the City were particularly demanding in terms of durability and quality of the surface, and standard of maintenance. Haywood inherited a situation, which had been forward-looking in respect of paving for in 1849 he commented 'the City Commissioners have I think tried almost every description of carriageway pavement'. Throughout his career he continued the practice of experimenting as new paving methods and materials became available and the results of these trials were given in reports to the Commissioners. Many of his reports exist in printed form.

-

Photo 1: A cobbled street — a rare survival — in Rye, Sussex.

Henry Tomkins prepared a report in 1872 for the Vestry of St. George's, Hanover Square giving a detailed critical survey of pavings used in the Metropolis. Percy Boulnois' 1895 textbook on road construction not only provides information on good practice, but also incorporates the responses to a questionnaire on the paving principles and practices of about 80 towns and metropolitan districts. Boulnois started his civil engineering career in 1865 as a pupil of J.W. Bazalgette at the Metropolitan Board of Works, and later occupied positions as municipal engineer to Portsmouth, Exeter and Liverpool. Henry Law, perhaps best remembered for his contributions to the Tay Bridge disaster inquiry, wrote a book on road construction published in 1855. The book went through many editions, being revised and extended first by D.K. Clark, and later by D.J. Wallis-Tayler for the sixth and subsequent editions.

-

Photo 2: Stone

setts in good condition

in Tower

Hamlets

Textbooks by highway engineers and surveyors, not unreasonably, dwell on good practice and successful developments. The less attractive condition of the streets can be found in the evidence to the Royal Commissions and in the writings of social observers as well as novelists of the period.

In the 1760s the cities of Westminster and London took the first significant steps towards the improvement of their streets. Noorthhouck, 5 writing in 1773, noted that impassioned complaints had been made about the state of streets in respect of surface and cleanliness. The typical carriageway was paved with large pebbles (cobbles) hazardous to horse and riders alike and maintenance was minimal. Flat pavements were provided for foot passengers 'but these were very negligently repaired'. As a result in 1765, Westminster obtained an Act for the better paving and cleansing of the streets with the consequence that 'the carriage way was paved with squared Scots granite, closely laid in gravel....' and streets raised or lowered as necessary to bring them to a level. The granite came from Aberdeen by sea and was laid on a gravel foundation. Footways were cleared of obstructions, provided with smooth paving, and defined by kerb stones. Following the example of Westminster, in 1776 the Corporation of London obtained an Act which not only allowed improvements but introduced an important principle in that they were enabled to levy a rate for street improvement and maintenance. The latter was a sound approach, for by the early Victorian era the City's streets were markedly better than elsewhere.

There followed a gradual improvement in paving but progress was very uneven across the Metropolis as the organisational structure of local government was very fragmented. The principal roads leading from London at the beginning of Victoria's reign were turnpikes and administered by many trusts. 6 In the course of the century the number of turnpikes was reduced by consolidation of trusts into larger bodies, notably The Surrey and Sussex Roads Trust. The formation of the 'The Commissioners of the Metropolis Turnpike Roads North of the Thames' (Metropolitan Roads Board) in 1826 improved the situation north of the river, the main public benefit being the Macadamising of roads. Disturnpiking of roads in the Metropolis proceeded but was not completed until an Act in 1871 ended tolls on roads in London, and the Metropolis Toll Bridge Act of 1877 freed all London's bridges from tolls. Other London roads were maintained by a multiplicity of vestries, paving trusts and paving boards. In 1844, St. Pancras alone had 19 paving boards, of whom, it was claimed, were 'often acting in opposition to each other'. In 1855, when travelling down the Strand one would pass through the 'empires of nine different paving boards', and in nearby Wellington Street there were four separate authorities within 100yds. In the 1870s, 77 miles of thoroughfare were in the charge of 68 separate bodies. The practical result was a wide variation in paving types, quality of construction and maintenance. The competence of the surveyors ranged from the virtually non-existent to those few worthy of the name of highway engineer. The 1855 Metropolitan Local Government Act created a two-tier system which left responsibility for 'local' roads in the hands of parishes and district boards who thus became the highway authority for their roads, while giving the newly-formed Metropolitan Board of Works responsibility for street improvements of a 'metropolitan' character. The untidy state of administration persisted until the formation of the London County Council in 1888. The City of London, however, continued independently of these local government changes although reluctantly it did have to co-operate with the Metropolitan Board of Works for certain street improvements.

Haywood's 1849 report provided a summary of carriageway paving then existing in the City of London (Table 1). 7 The City was then by far the best provided for in quality of paving, and as early as 1848 granite setts provided the bulk of paving.

| Table 1: Varieties of paving in the fifty miles of carriageway within the City in 1848. | |

| 1 | Small quantity of ancient pebble paving (Approximately 1 mile). |

| 2 | Cubed granite of various sizes — 6", 5" & 4" wide — forming the bulk of carriageway paving (28.5 miles). |

| 3 | Various types of wood paving (¾ mile). |

| 4 | A very small & isolated portion of water-bound Macadam road in Finsbury Circus (¼ mile) |

| 5 | Courts, alleys etc. paved with flag stones.(16.5 miles). |

PERFORMANCE CRITERIA

Boulnois 3 listed the target attributes of a carriageway paving as:

- Impermeability

- Durability

- Foothold

- Ease of traction

- Adaptability to all gradients

- Adaptability to all classes of traffic

- Noiselessness

- Non-manufacture of mud or dust

- Ease of cleansing

- Ease of repairs

- Economical in first cost and maintenance

- Not influenced by climatic changes

- Good appearance

The relative importance of these factors depended on local circumstances although, it must be said, minimum cost appears to have been the only concern of many road authorities.

The Victorian era was that of the horse-drawn society and the requirements of horse-drawn traffic dominated the selection of paving ('courses for horses') notably in respect of providing a grip for horses' hooves, especially necessary on gradients which would affect the load a horse could pull, and the wear and tear on beast and vehicle. The number of horses in London can only be estimated but the data in Gordon writing in 1893 8 yields a figure of about 100,000. He estimated from the 1891 daytime census of traffic in the City of London that probably 100,000 horses crossed its boundary during a working day. Ease of cleansing of the paving was a major issue for each horse generated between 3 and 10 tons/year of manure and urine, a substantial proportion of which was deposited on the roads. In the 1870s it was estimated that in the case of a main thoroughfare, 3 to 4 cartloads of horse dung per mile had to be removed each day. In addition, very large numbers of sheep, cattle, and pigs were driven to and from London markets so adding to the excrement load.

TRAFFIC VOLUMES

A limited number of traffic surveys exist, the more useful of which include both the number and type of vehicle. Table 2 is an example taken from a traffic survey on one of the busier streets in the City as reported to a Royal Commission in 1843. 9 The large number of heavy vehicles in Ludgate Hill/Street can no doubt be accounted for by such traffic avoiding the steep hills leading in and out of the Fleet Valley (Holborn Viaduct had not then been built). The City of London throughout the Victorian era possessed a uniquely high traffic density and so provided the toughest test bed for the performance of road constructions.

| Table 2: Traffic through Ludgate Hill and Ludgate Street* | |

| (counted on 10 March 1843 from 6am to 6pm) | |

| Cabs & gigs | 1238 |

| One-horse carts | 1516 |

| Omnibuses & stages | 1174 |

| 2-horse private carriages & hackney-coaches | 402 |

| Waggons, 3-horse and upwards | 319 |

| Other vehicles | 269 |

| Saddle-horses | 204 |

| Hand trucks | 80 |

In 1871, Haywood wrote of the 48 miles of granite paving in the City that 'of these, about 9 miles are subject to the largest, most concentrated, and most destructive traffic in the world', and that wear from traffic led to a large consumption of granite annually. In 1870, 11,900 vehicles passed along Cheapside in a 24 hours period and the connecting Poultry had 9,600 vehicles. These two streets were probably the most demanding of paving in the City; part of their re-paving history is given in Table 3. 10

| Table 3: A History of Paving in Cheapside and Poultry | |

| CHEAPSIDE | |

| 1829 | Aberdeen granite 6 in. x 9 in. |

| 1843 | Wood |

| 1846 | Granite |

| 1847 | Granite |

| 1861 | Newly paved |

| 1870 | Val-de-Travers compressed asphalte |

| POULTRY | |

| 1841 | Wood |

| 1843 | Wood |

| 1846 | Part granite |

| 1852 | Part granite |

| 1859 | New stone and granite trams |

| 1862 | Part cast-iron pavement & Redman's iron trams |

| 1863 | As above |

| 1865 | New granite and Carey's iron tooth-edged trams |

| 1870 | Taken up because in a bad condition, replaced with Val-de-Travers compressed asphalte |

ROAD FOUNDATIONS

By the time Victoria came to the throne, there was beginning to be a recognition that a sound foundation was necessary if a road was to perform adequately. Nevertheless, at mid-nineteenth century, Henry Law 4a in 1855 put British roads into one or other of three categories:

- 1. Those with no foundation, with the covering materials laid directly on the soil, a type that included 'by far the largest proportion of the roads in the country'.

- 2. Those with a foundation of concrete.

- 3. Those with a paved (i.e. stone) foundation.

At that time, concrete was beginning to be used. The Brixton road had recently been constructed with a six-inch depth of lime concrete as foundation upon which two three-inch layers of well-compacted gravel were laid. The Walworth road had also been provided with a sub-stratum of nine inches of concrete upon which was laid six inches of mixed gravel and Kentish ragstone.

Although Macadam advocated a foundation which would yield somewhat so reducing the deleterious effect of impact loading, the majority view by mid-century was that a firm, solid foundation was needed. The stiffness of a road base constructed with concrete was comparable to that achieved by a Telford-type foundation and so was the preferred solution for those parts of the country remote from sources of suitable stone.

MACADAM ROADS

On Victoria's accession to the throne in 1837, in spite of some improvements, most of London's streets were in a poor state and, even if constructed reasonably well, generally were poorly maintained. John Loudon Macadam's own recommendations were quickly adopted and within a few years most roads in the Metropolis were of water-bound macadam. His method depended on the careful selection in sizing and placing of stone such that stones would interlock, any voids then being would be filled by fine material from stone crushed either by rolling or by traffic, and washed into the interstices by water. The end result would be a road construction with a crust more-or-less impervious to the ingress of water. Macadam recognised that water penetrating to the soil below the road construction was the prime cause of paving failure. The very necessary compaction of the layers of stone was undertaken either leaving the road to be consolidated by the passage of traffic or else by rollers. The latter method was much more effective and the ratio of hard to soft material when rolled was 85/15%, compared to a traffic-consolidated road where the ratio was 60/40%. 11 Until the introduction of steamrollers, consolidation was achieved by 'heavy garden rollers' — a typical one being of cast iron, 5ft long x 4ft diameter, and weighing about 4 tons, drawn by two horses. Steamrollers were introduced in the 1860s, the first Aveling roller of 1865 was basically a traction engine towing a large roller. The first purpose-designed steamroller followed in 1866 when Aveling combined the engine and roller into the one machine and it attracted much attention when used in London's Royal Parks. In 1871, Aveling & Porter introduced a design of the now-familiar configuration and thereafter steamrollers were generally adopted and led to a marked improvement in the quality of Macadam road construction.

The increase in both numbers and weight of vehicles on main thoroughfares led to the rapid deterioration of macadam roads. Heavy vehicles ground the upper layers of stone to dust and the road could only be kept in good condition and dust and mud controlled by prompt and frequent maintenance. The dust was dealt with by first watering, then the mud was scraped off and any ruts filled. The damage caused by a heavy vehicle can be illustrated in that a fully-loaded omnibus weighing over three tons was likely to leave a ½ in. deep wheel track on a wet road; the cumulative effect of such damage, unless repaired promptly, would lead to rapid disintegration of the surface.

A particular problem, in the London area, was identified by Macadam: 'The gravel of which the roads around London are formed is the worst; because it is mixed with a large proportion of clay, and because the component parts of gravel are round, and want the angular points of contact, by which the broken stone unites and forms a solid body; the loose state of the roads near London, is a consequence of this quality of material, and of the entire neglect, or ignorance of the method of amending it.' 12

Flint used in Essex and Sussex was much better than gravel but it was apt to fracture readily under load.

Broken granite stone became the preferred material of several authorities, although more expensive, for it possessed both toughness and the shape to facilitate interlocking. Macadam expected his roads to wear at a rate of 1 to 4 in./year. depending on traffic.

A Macadam road tended to be insanitary because of the penetration of horse manure and urine, giving rise to contaminated mud or wind-blown dust. Boulnois 3 wrote 'The Paving of Streets is next in importance to the sewerage of the Metropolis, and it is only by a good combination of the two, that true sanitary measures can be rendered complete and permanent'. Apart from the contamination aspect, both granite and flint dust were recognised as causing lung disease. Boulnois observed that when a dust-free surface was provided, then public health in the neighbourhood improved noticeably. In dry weather, a Macadam road needed spraying with water once or twice a day to lay the dust — the water cart was a regular feature of the Victorian street scene, sometimes with the spraying being paid for by frontagers. It perhaps should be stressed that the dust problem was identified as a serious problem long before the coming of the motorcar, the tyres of which would suck out fine material. The advent of the bicycle as an increasing popular means of transport and a vocal body of cyclists had already served to hasten the demise of the Macadam road.

By 1848, the City of London had only one short section of Macadam remaining but the City was an exception for, whatever its limitations, the Macadam method was economically attractive and certainly a great improvement on what had existed previously. It provided a good footing for horses and the noise generated by horses' hoofs and vehicle wheels was low. The Macadam road continued to be the standard for lightly trafficked roads well into the twentieth century but was ultimately superseded by bituminous pavings, although some survives in private roads.

TARRED MACADAM AND TARMACADAM

The tentative use of coal tar as a surfacing material began in the early 1820s but the first road to employ tarred gravel was a two-mile section of road out of Nottingham in 1840; Huntingdon High Street followed suit in 1845. Whether or not these were strictly of Macadam type is unclear but without doubt the intention was to virtually eliminate the dust problem. In the case of the 'tarred Macadam' road, tar was sprayed onto the finished surface. An improved approach was to pre-coat the stones for the top layer with tar before laying; this was the tar-macadam road — often abbreviated to 'tarmac' in common parlance, a term often misapplied to asphalt roads (it is also a trade name). Although dust control was the original intention behind tarring, it was found that tarring extended the life of the road. This outlet for tar was to prove for gas works a profitable source of income for one of their by-products of coal gas manufacture.

GRANITE SETTS

Noorthouck, referred to earlier, noted that Westminster in the early 1770s had introduced 'squared Scots granite *, closely laid in gravel'. The next recorded use of granite blocks was in 1824 and the subject of a report by Thomas Telford for the parish of St George's, Hanover Square. Here the surface was of varying sizes of roughly squared blocks on a poor foundation of broken stone, the result was that the surface became uneven and unsafe for horses. The lack of an adequate foundation, according to Taylor writing in 1850, was general in the Metropolis, for the practice had been to lay setts directly on the sub-soil. An experiment in Birmingham in 1838 followed Macadam's method but with the top layer of stones replaced by granite blocks. 13 The surface successfully withstood heavy waggon traffic and led to a similar pavement being constructed five years later at Euston Station, which was to become known as the 'Euston Pavement'. It employed stone from Mountsorrel in Leicestershire and the granite (granodiorite) was described as possessing 'an absence of those glassy qualities so observable in almost any other paving'. The stone blocks were 3 to 4 inches deep, 3 inches wide, and 4 inches in length, and dressed squarely. What has been called the first 'modern' application of setts was in 1840 on Blackfriars Bridge where the setts were laid on a bed of concrete and jointed with mortar. The City of London followed with a trial of the 'Euston Pavement' in 1844/5 in Watling Street but this had to be re-laid in September 1848, not because of any inherent defect in the road as constructed but because of careless restoration of the road after pipes had been laid. The satisfactory performance of granite setts was rapidly to lead to their adoption by the City such that by 1848 setts were in general use in most of its streets (Table 1). There was also a rapid expansion in their use elsewhere in the Metropolis and soon they were to be used widely for streets in the rest of London (Table 4). Large quantities of granite were being brought into the Metropolis by canal, rail, and sea.

-

* To avoid confusion the description 'granite' is used here in the commercial sense that is often inaccurate in the geological sense — see the appendix for further explanation.

The width of sett was determined by the need to provide a good grip for the horse's hoof and so was typically 3 or 4 inches wide. The preferred lengths were between 4 and 9 inches, longer blocks were avoided as they had a tendency to tilt under load. Although the term 'sett' is applied to any dressed granite paving stone, there were also local names for different sizes of block.

The setts had a layer of sand intervening between them and the foundation to act as a cushion thus minimising the fragmentation of the stone by impact loads. In early installations, the joints between setts were filled with sand or gravel pressed into the gap. Later practice was to use a cement grout but a number of authorities used fine gravel compacted into the joints into which hot tar or pitch was poured. The width of joint and the efficiency of grouting had considerable effect on the life of the surface. If the spacing was wide and the grouting poor the edges of setts wore away producing 'petrified puddings' leading to a rough, noisy surface which was difficult to clean.

In his 1849 report Haywood concluded that granite was best suited for heavily-trafficked streets, and that Aberdeen granite setts were probably the best compromise in terms of first cost, durability and absence from slipperiness. He undertook systematic testing in order to develop a specification for stone setts and tried different sizes of stone and types of granite in compartments in the same street. He noted that very hard stone rapidly became polished by the passage of traffic providing a poor foothold for horses. In contrast, more friable granites were better as they wore to expose fresh surfaces, but this also meant that they wore more rapidly. Part of Newgate Street had been paved in 1851 with setts from Penmaenmawr Quarries in North Wales as an experiment but this material proved to be unsatisfactory. After repeated complaints about slipperiness and noise, it had to be replaced in 1853 by Aberdeen granite.

For secondary streets, worn material from main streets was redressed, after further wear their final use was either in streets with little traffic or crushed to provide material for Macadam roads or foundations. In addition to that from Aberdeen, granites from Guernsey and Mountsorrel in Leicestershire were used in quantity in the Metropolis later in the century. Other sources included Cornwall, Ireland, and Scandinavia. Clee Hill setts were sent by rail to the London area; they are known to have been used in Ealing and Windsor.

The disadvantages with granite paving were dust resulting from wear, and noise. In a discussion on Taylor's paper 14 at the Institution of Civil Engineers in 1850, there was considerable debate about the rate of wear but Haywood measured the wear on a large sample of setts removed from Watling Street and concluded they lost on average of 1/16 inch/year. The rate of wear, of course, was dependent on the quantity and type of traffic, and stone, even from the same quarry, had variable characteristics. As setts were eroded by traffic the granite dust became a health hazard in dry weather and spraying with water was necessary to control it. When washed into the sewers, granite dust tended to create a dense deposit that was difficult to clear. The City of London's Medical Officer of Health, Dr. Letheby analysed dried mud from its streets showing the content as: horse dung 57%; abraded stone 30%; and abraded iron 13% (by volume or weight?). 15 Shopkeepers complained that they lost a substantial amount of their goods as a result of dust from the streets. Noise generated by iron-tyred wheels on setts, especially when worn, was a frequent complaint of residents and businesses. Noise was also alleged to be the cause of nervous afflictions.

Towards the end of the century, when wood and asphalt surfaces prevailed, granite setts continued to be used in preference to such surfaces where a good foothold for horses was essential, as when the gradient exceeded 1 on 60. They were also used where wear was likely to be high, as at road junctions. In a street where setts comprised the general surface, short sections of tar-macadam or asphalt were sometimes laid to reduce noise outside sensitive locations such as hospitals and churches. Setts continued to be used for the first half of the following century especially where the traffic was heavy and where noise of little account as in railway depots and docks. Much remains in situ although often not visible, as the surface has been upgraded by an overlay of a bituminous material.

| Table 4: | Types of pavings in use in London Districts in the 1890s | ||

| (miles, unless otherwise stated) | |||

| District | Granite | Wood | Asphalt |

| Bermondsey | 16 | 0.5 | |

| Camberwell | 4 | ||

| Chelsea | 4.4 | ||

| Greenwich | 4 | 0.5 | |

| Fulham | 0.06 | 4.5 | 0.176 |

| Hammersmith | 0.14 | ||

| Holborn | 9.2 | 1.2 | 2.23 |

| Kensington | 5.2 | 196,314 sq yds | |

| Mile End Old Town | 5.5 | ||

| Lambeth | 1.75 | 8 | |

| Newington | 3.14 | 0.5 | 0.25 |

| Paddington | 1.09 | 8.08 | |

| Plumstead | 2 | ||

| St. George in the East | 14 | ||

| St. Giles | 9 | 0.75 | |

| St. George's, Hanover Square | 5 | 12 | |

| St. James, Westminster | 0.75 | 3.5 | 5.25 |

| St. John, Hampstead | 0.5 | 1.25 | |

| St. Leonard, Shoreditch | 15 | 0.25 | 1 |

| St. Martin-in-the-Fields | 1 | 3.75 | 1 |

| Whitechapel | 18 | ** | 0.5 |

| St. Mary, Islington | 12 | 0.5 | 0.5 |

| St. Mary, Battersea | For tram tracks | ||

| St.Olave | 4,326 sq yds | ||

| Westminster | 135,500 sq yds | 48,055 sq yds | |

| Woolwich | 2 |

SETTS USED WITH OTHER PAVING TYPES

It was common for granite setts to be used in combination with other types of paving in a street.

a. Granite Tracks.

One means of economising on the use of granite was to provide either a central track or side tracks paved with setts leaving the rest of the surface macadamised. The intention was for heavy vehicles to use the tracks, leaving the Macadam surface for light vehicles and horses. The reports by the Committee on Highways and the Use of Broad Wheels in 1808/9 commended paving of a 20ft wide section in the centre of roads in the immediate vicinity of London, roads which would have been turnpiked at that time. A variation of the use of paved tracks in given by Hughes16 writing of the Epping Road: 'This road, as far as Stratford, is composed principally of Mountsorrel syenite; in addition to which, from Whitechapel church, where the street-paving ends, as far as Bow, a trackway, of eight feet wide on each side, is pitched with regular granite paving stones, similar to street pitching. This is of great service for slow heavy traffic, by which the trackways are chiefly used.'

b. Stoneways

'Stoneways' or 'stone tramways' were used to a limited extent in London. The stoneway consisted of two parallel tracks of granite slabs laid such that vehicle wheels would run on a smooth surface and so reduce tractive effort, setts being left in between the slabs to provide a good grip for hooves. The granite blocks were called 'trams' or 'wheelers'. It was reckoned that the tramway enabled one horse to do the work of two. The disadvantage of such tracks was that wear was concentrated upon them and they had a limited life (Photo 3).

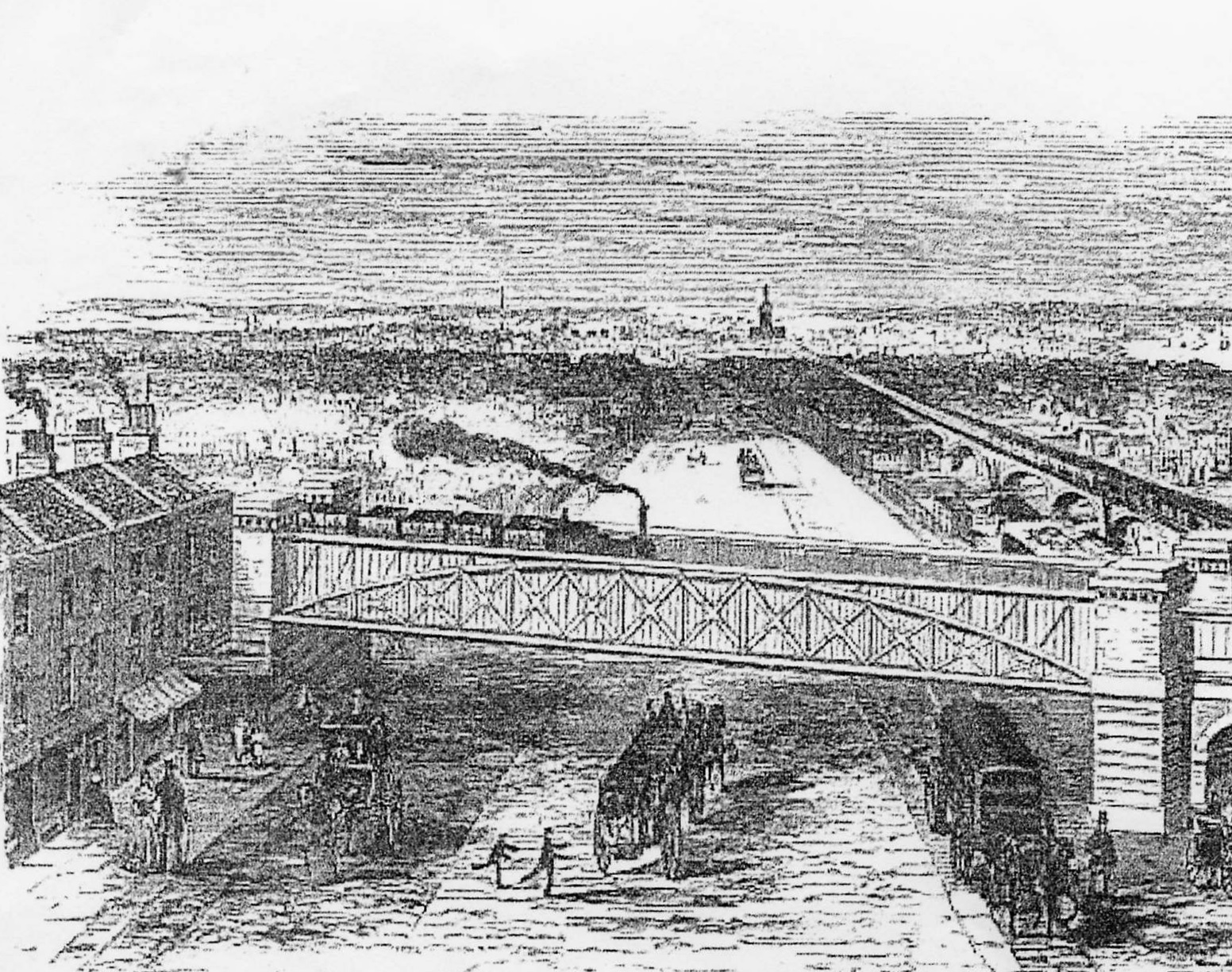

Possibly the earliest example in London was that laid along two miles of the Commercial Road in the East End to cope with the heavy vehicles travelling from the expanding docks to the City. By the 1870s, 300,000 tons/year of dock traffic passed along the road with a flow of about 300,000 vehicles/year. The road had been built in stages from 1803 onwards and the increase of traffic by 1829-30 led to 'a stoneway being laid along the southern side of the road. It was formed of blocks of Aberdeen, Guernsey and Herm granite eighteen inches wide, twelve inches deep and 2½ to 10 feet long in the manner of a tramway over which the huge vehicles could be drawn with ease from the docks, 17a, b, c. The traffic was such that the Aberdeen granite lost about 4 in. of its thickness in just 4 years. It had been the intention to have a stoneway for each direction of traffic but the additional toll to use the stoneway was a deterrent and the northern one was never built. An engraving of 1851 reproduced in Figure 1 shows the road at Stepney Station. The stoneway is shown with stone slabs rather than setts between the tracks. The north side of the road appears to be paved with the remainder of the road gravelled.

A succession of reports on sanitary matters in the 1840s commended stoneways as did Le Neve Foster in a report in 1875. 18 The latter report included an appendix showing in detail the construction of the stoneways of Milan. There seems to have been only a few applications of 'stone tramways' in the public highway in London; they are known to have been used in some streets in the City of London and also in the docks. 19 Cast-iron tramways were laid in Poultry, a narrow but very busy City street where rutting of the surface was a problem.

c. Streets with tramway tracks

Where tram tracks were laid, as far as can be determined, it was universal practice for setts to be laid between and on either side of the tracks. The setts served to provide stability for the rails especially when the street was unpaved, and they provided a good grip for TEXT MISSING>>>>>>>>>>>>>>>>>>

-

Photo 3. A 'stoneway' (in Shrewsbury)

-

Figure 1: Commercial Road at Stepney Station in 1851, showing the stoneway in operation.

-

Photo 4. Setts visible below bituminous overlay

KERBS

TEXT MISSING>>>>>>>>>>>>>> hough the performance requirements for kerbs were less onerous than for carriageway paving, they were most commonly made of granite. Whitehead 21 records that in Bell Street, Paddington, kerbs were of basalt, Peterhead granite, diorite and Cornish granite. Like setts, kerbstones provided a useful source of ballast on ships when sailing with little or no cargo. Sandstone and limestone kerbs may have a limited use as one reference describes such materials as inferior. By the end of the century Aberdeen granite had virtually ceased to be used because of low cost Norway granite.

CONCLUSIONS

Old photographs show that, in many cases, the surfaces do not conform to those described thus far. Sometimes paved roads were constructed with stones of random shape, and where dressed stone is used a mixture of sizes had been employed. Such evidence supports the statement of Paget, who in his 1870 report thought the consensus was that London streets were 'well-made but barbarously maintained'. The second part of this article will deal with the development of smoother, quieter, and more hygienic surfaces.

REFERENCES

[WH Report = printed report by William Haywood to the Commissioners of Sewers of the City of London.]

1. D.G. Clow, William Haywood and Municipal Engineering in the Victorian City of London, Trans. Newcomen Soc. 72, 2001 p.39-76

2. H.T. Tomkins, Report to the Committee of Works of the Vestry of St. George, Hanover Square upon the Pavements in use in the Metropolis, 3 Dec. 1872. (copy in I.C.E. Library)

3. H.P. Boulnois, The Construction of Carriageways and Footways, London, 1895, p.65.

4a. H. Law, Rudiments of the Art of Constructing and Repairing Common Roads, 1st ed., London, 1855.

4b. H. Law & D.J. Clark, The Construction of Roads and Streets, revised by A.J. Wallis-Tayler, 8th edition, London, 1914.

5. J. Noorthouck, The New History of London, 1773, pp.414-415 cited in L.W.G. Malcolm, Early History of the Streets and Paving of London. Trans. Newcomen Soc., XVI, 1933-34, p.90.

6. T.F. Ordish, History of Metropolitan Roads, London Topographical Record, VIII, 1913. p.1-92.

7. WH Report, Questions upon the subject of Pavings... and his answers thereto, 1849.

8. W.J. Gordon, The Horse World of London, London, 1893.

9. Parliamentary Paper: PP.1844, XVII, First Report of the Committee of Inquiry into the State of Large Towns and Populous Districts. Evidence of Prof. B. Williams, Q5861.

10. WH Report... upon Granite and Asphalte Pavements. 24 Jul. 1871.

11. T. Aitken, The Maintenance of Macadamised Roads, Min. Proc. Instn. Civ. Engrs., CXXII, 1894-5. p.215.

12. J.L. Macadam, Remarks on the Present System of Road Making... London 1827, p.158f. It may be noted that John Loudon McAdam had no surveyor appointments in the London area although he was not averse to complaining about the state of London roads. His son, James McAdam (later Sir James Nicholl McAdam) seems to have been a collector of surveyor posts, having acquired 64 in the country over the years including the most prestigious position of Surveyor to the Commissioners of Metropolis Roads — this gave him control over most of the principal roads in and around the Metropolis.

13. W. Taylor, Observations on the Street Paving of the Metropolis; with an Account of a Peculiar System adopted at the London and North-Western Railway Station, Euston Square, Min. Proc. Instn. Civ. Engrs., 26 Feb. 1850, pp.214-219.

14. Haywood in discussion on W. Taylor, ibid, pp.222-224.

15. Letheby, Report on the Sanitary Condition of the City of London, 1856-7, p.8 cited in E. Chadwick, On the Sanitary and Economic Advantages of Smooth and Impermeable Street Surfaces, from Society of Arts with Corrections and Additions. 1871, p.3.

16. S. Hughes, General Survey of the Principal Metropolitan Roads in Law, 1855, op. cit.. p.8.

17a. S. Maddocks, Commercial Road, The Copartnership Herald, 11, p.21. Nov 1932.

17b. T. Smith, The Commercial Road Stoneway, GLIAS Newsletter 77, p.2.

17c. T. Smith, Stone Tramways, GLIAS Newsletter 83, p.4.

18. P. Le Neve Foster, Report on the Application of Science and Art to Street-Paving and Street-Cleaning of the Metropolis, 1875.

19. C. Ellmers & A. Werner, Dockland Life: a Pictorial Record of London's Docks 1860-1970, (Museum of London/Mainstream Publishing, 1991). p.32 a photograph of the North Quay, London Docks has a stoneway together with 'branches' off it

20. D.K. Clark, Tramways: their Construction and Working, 1894. Reprinted by Adam Gordon, 1992.

21. J. Whitehead, The Growth of St. Marylebone and Paddington, Jack Whitehead, 1989. p.120.

APPENDIX

THE GRANITIC FAMILY OF IGNEOUS ROCKS

'Granite' is a well-defined rock category in geology but has been used loosely by other disciplines when it encompasses other types of igneous rock. Stone from Mountsorrel in Leicestershire has been variously described as granite and syenite but the British Regional Geology classes the rock as granodiorite. The Clee Hill Granite Co. actually produced dolerite setts! A classification that encompasses rocks mentioned in this paper is given in the table below.

| Types of granite mentioned in the text | |||

| Acid | Intermediate | Basic | |

| Plutonic (completely crystalline, coarse grained) | Granite Granodiorite |

Syenite Diorite |

|

| Hypabyssal (completely or almost completely crystalline, fine grained) | Quartz porphyry | Syenite porphyry Diorite porphyry |

Dolerite |

| Volcanic — incompletely crystalline, very fine grained or non-crystalline (glassy) | Basalt |

As a general statement, the coarse-grained plutonic rocks performed best in carriageway situations.

© GLIAS, 2004